About Global Lift Used Forklifts Carlsbad

Global Lift Carlsbad - Regardless whether you have a new forklift fleet or used forklifts, your machinery needs to be maintained to ensure safety and productivity. Careless forklift operation could result in added expenses due to damage and abuse. There are easy ways to identify operator practices which indirectly contribute to costs related to the incorrect operation of Caterpillar lift trucks or forklifts. The tips below will truly help you lessen operating costs while ensuring a long life for your machinery.

Regardless whether you have a brand new forklift fleet or used forklifts, your machinery needs to be maintained to ensure productivity and safety. Careless forklift operation could result in additional costs because of damage and abuse. There are easy ways to identify operator practices that indirectly contribute to costs associated to the incorrect operation of Caterpillar forklifts or lift trucks. The tips below would really help you lessen operating expenses while ensuring a long life for your machinery.

Causes Of Facility and Forklift Damage

Incorrect Forklifts. For the efficient and safe performance of a forklift, it is essential to choose the right lift truck equipment for the application. One of the most common mistakes is using the wrong type of forklift or alternatives for the specific task. Equipment could suffer premature wear and tear. Parts could be subject to failure. Make sure that the lift truck is fitted with the right tires and that they are not worn.

Incorrect Forklift Operating Practices. A common cause of impact damage is incorrect forklift operating practices. Damage to product, machine or facilities may happen while navigating around things. A congested work area lends itself to impacts. Like for example, pushing pallets, called "Bulldozing", can damage the transmission and wear tires.

Unsafe Forklift Lifting and Speeding. Incorrect lifting practices can result in personal injury and equipment damage. Common errors consist of lifting very high and traveling too fast. A load that is too heavy can cause the forklift to tip over. The operator must make sure that the forks are level.

The forklift is a material handling machine utilized to lift and transport loads from one place to another. Each part of a forklift has a specific function. Different parts could be used to move the load either horizontally or vertically.

The parts utilized to lower and lift the load is referred to as the forklift mast. There are various types of masts utilized for lifting loads to various heights: simplex, duplex, triplex and quad.

Forklifts have four various ways of being powered: gas, electric, diesel and propane. The battery is situated inside the cab beneath the seat. The propane tank is on the rear of the truck. The fuel tank on diesel and gas forklifts is under the back of the truck.

Located within the middle of the truck is the forklift cab. This is where the operator sits and accesses all the informational gauges and controls. The gas pedal, steering wheel, brake, lifting controls and tilting controls are all located inside the cab.

Carrying all the largest forklift parts is the frame of the truck. This consists of the counterweights situated at the back that prevents the truck from tipping over when loaded. The frame includes the overhead guard which protects the operator. The undercarriage holds the wheels, driveshaft and axles.

Forklift certification really helps to make sure that companies are in compliance with regulations and legislation. Forklift operators must undergo certification before being permitted to operate equipment. In places where certification is not required by law, training is helpful for those looking for industrial jobs. Certified individuals are often selected over other applicants because of this training. Certified forklift drivers are usually paid more than those who are not licensed. For businesses, having correctly trained forklift operators means better productivity, fewer workplace accidents and fewer product damage during unloading and loading. When companies abide by governmental guidelines by providing training to their employees, they can attain better ratings on their safety inspections, possibly decreasing insurance expenses.

Formal forklift training is recommended to help staff and supervisors get licensing. It will be easier for those with a forklift certification to look for warehouse work as the license will show to prospective employers that the applying has certain required skills. A forklift license is suggested because o the advantages to both the worker and the company. A skilled driver saves resources due to less incidents, that means savings on costs connected with hospitalization or loss of time. A licensed forklift operator could be depended upon to work more effectively and efficiently than some body who is not trained.

The length of a formal forklift training program will differ depending upon several things, like for instance the kind of forklift used in the instruction, class size, and aptitude and experience level of trainees. Those training would be required to pass a practical exam and written test before getting the license. Upon successfully completing a formal training program, graduates would be certified to be able to obtain work in various companies.

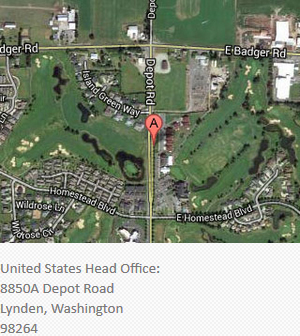

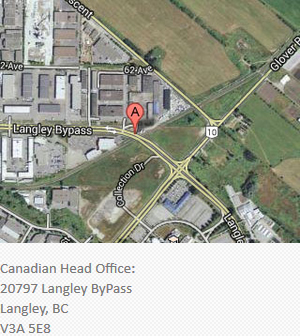

Contact Info

Questions or Comments